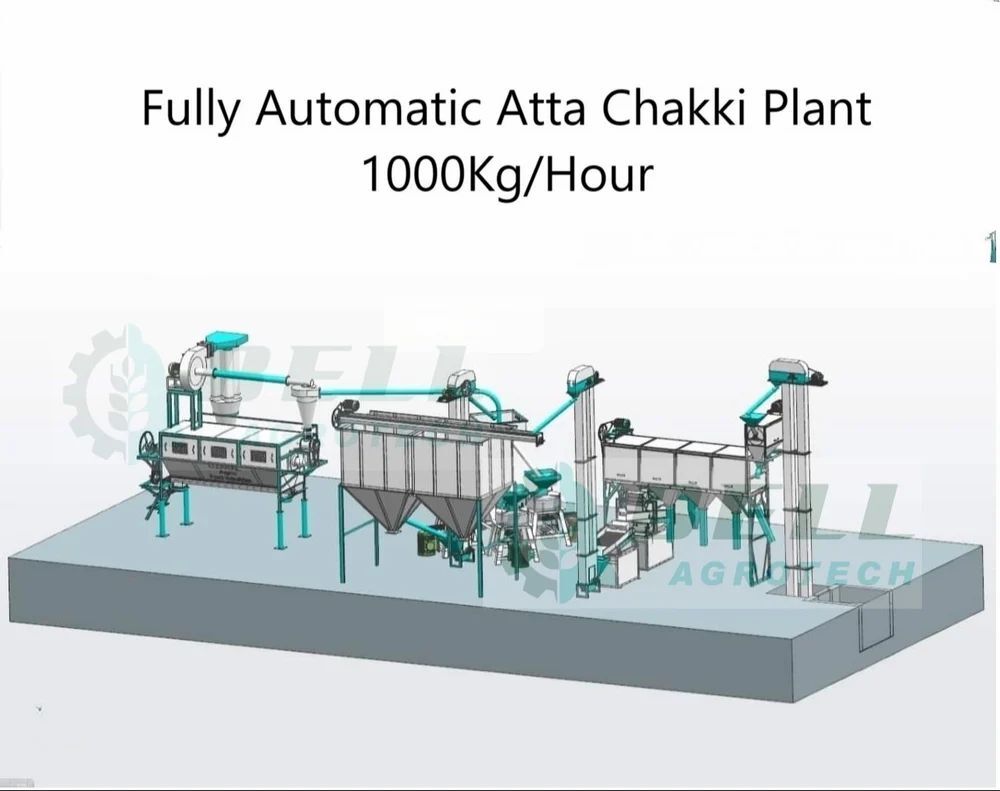

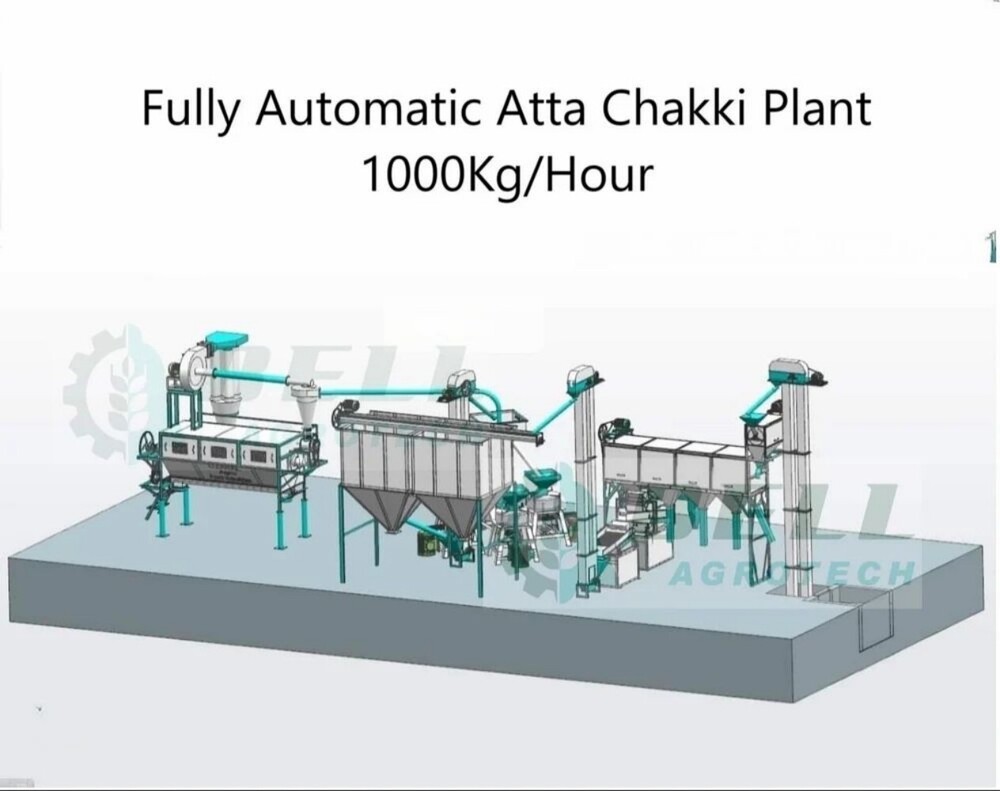

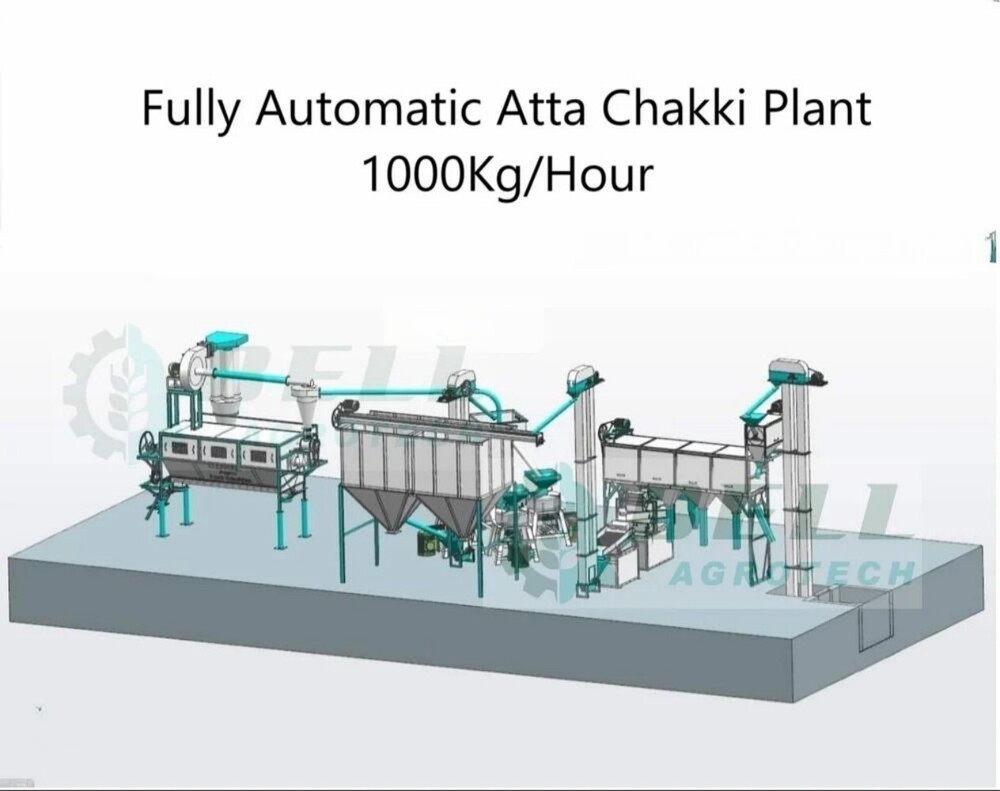

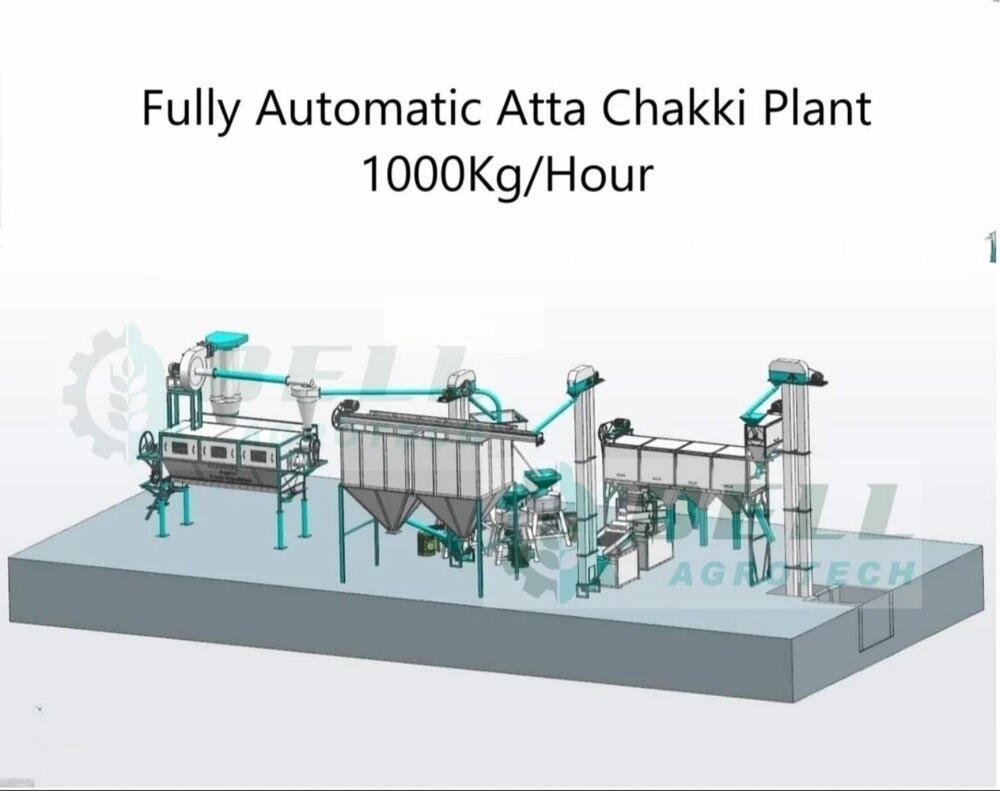

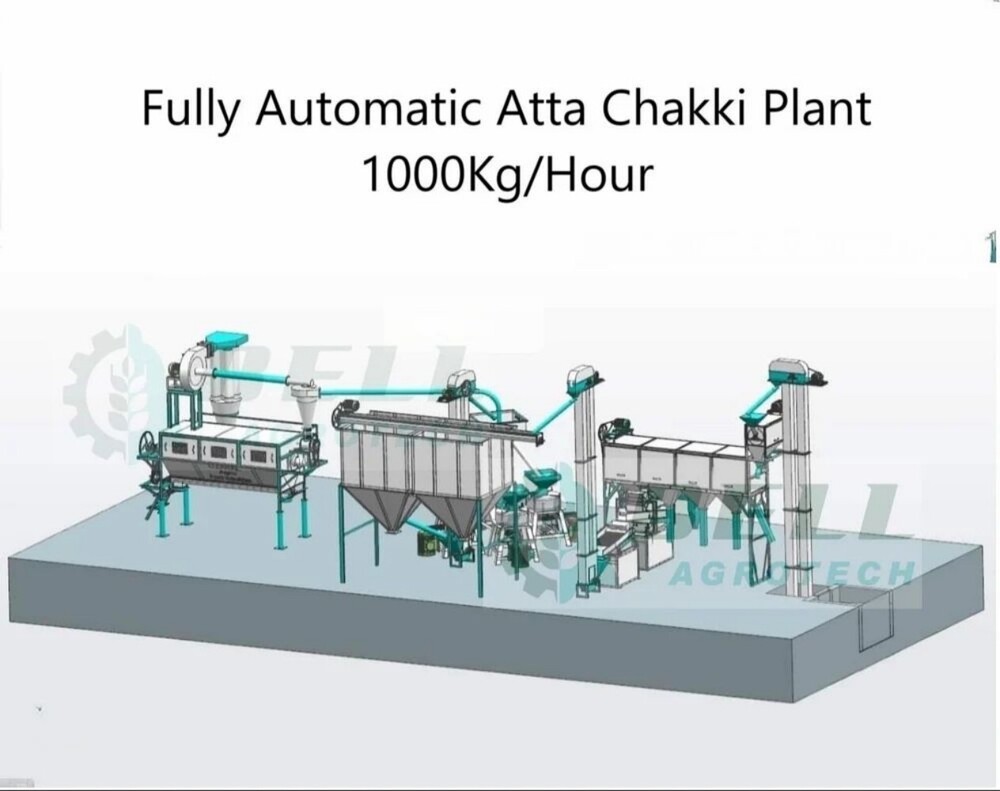

Fully Automatic Atta Chakki Plant

700000 INR/Unit

Product Details:

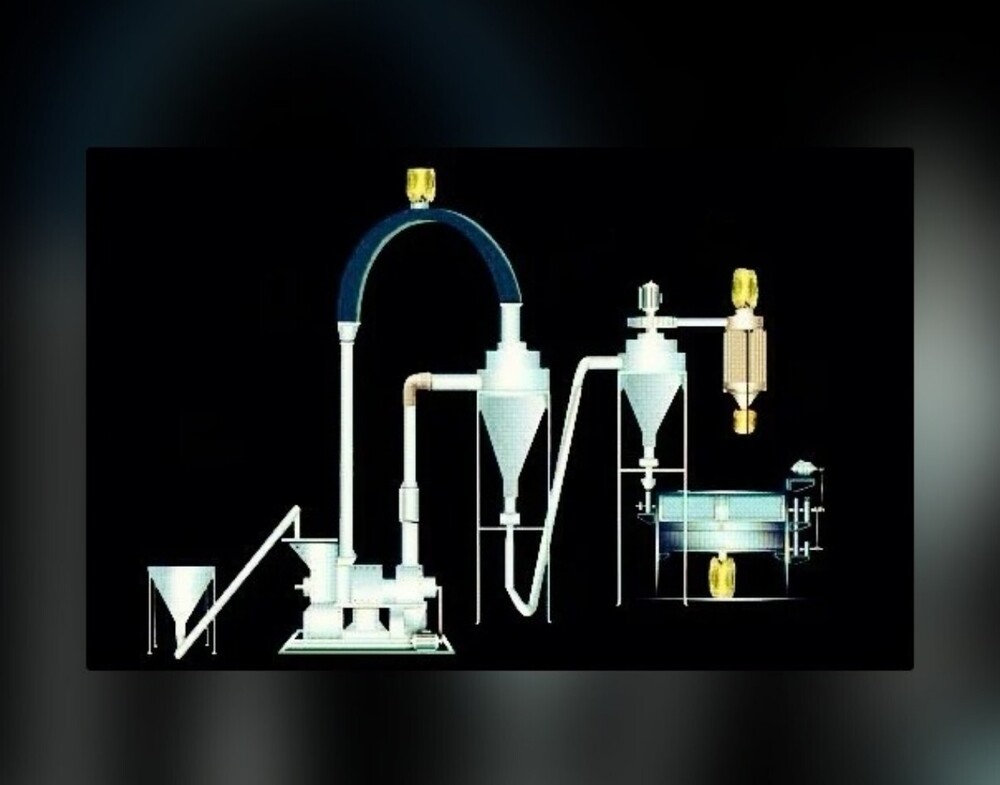

- Product Type Fully Automatic Atta Chakki Plant

- General Use Industrial

- Type Flour Grinding Machine

- Capacity requirement based m3/hr

- Weight (kg) requirement based Pound (lb)

- Automatic Yes

- Control System Manual

- Click to View more

X

Fully Automatic Atta Chakki Plant Price And Quantity

- 1 Unit

- 700000 INR/Unit

Fully Automatic Atta Chakki Plant Product Specifications

- requirement based m3/hr

- Yes

- Yes

- Flour Grinding Machine

- requirement based Perch

- requirement based Pound (lb)

- Rice

- requirement based Megaampere ( MA)

- Industrial

- Yellow

- Fully Automatic Atta Chakki Plant

- Lower Energy Consumption

- Manual

Fully Automatic Atta Chakki Plant Trade Information

- punjab, up

- Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Asia

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email